Understanding the basics of air filtration

What Happens During Air Filtration?

Air filtration is a process that removes solid particles, liquids, and gases from the air using a filter medium. The main goal is to improve air quality by capturing contaminants such as dust, pollen, smoke, and even microscopic particles. Filtration systems use various methods and filter media to trap these unwanted substances, making the air safer to breathe in homes, offices, and industrial environments.

Types of Filters and How They Work

There are several types of filters used in air filtration systems, each designed for specific applications. Some of the most common include:

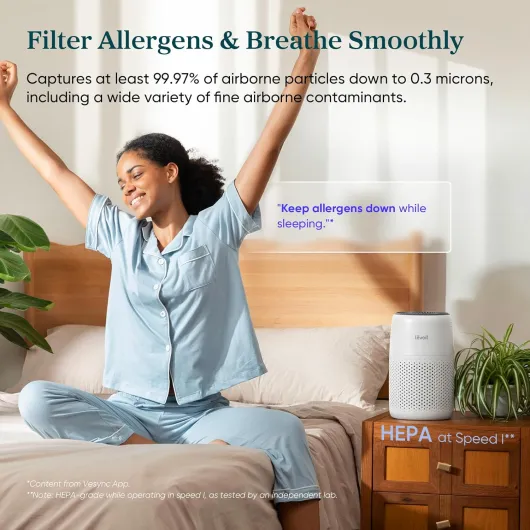

- Mechanical filters – These use a physical barrier, like pleated fabric or fiberglass, to trap particles. HEPA filters are a well-known example, capturing at least 99.97% of particles as small as 0.3 microns.

- Activated carbon filters – These are effective for removing odors and gases by adsorbing them onto a porous carbon surface.

- Membrane filtration – Used in both air and water treatment, these filters use a thin membrane to separate particles from fluids or gases. This method is common in pharmaceutical industry and water treatment applications.

Other filtration methods include vacuum filtration, gravity filtration, and flow filtration, each chosen based on the specific needs of the filtration process.

Why Filter Media Matters

The choice of filter media is crucial in determining the efficiency and application of a filtration system. For instance, industrial filtration often requires robust materials to handle high volumes of air or fluid, while pharmaceutical applications demand sterile, high-efficiency filters to maintain product safety. The filter medium can be made from paper, fabric, glass fiber, or synthetic materials, each offering different benefits for capturing solids, liquids, or gases.

Filtration Beyond Air: Other Applications

While air filtration is a primary focus, similar principles apply to water treatment, oil and gas industries, and even food processing. In these sectors, filtration systems are designed to separate solids from liquids, or liquids from gases, ensuring product quality and process safety. For example, filter cartridges and membrane filtration are widely used in water treatment and pharmaceutical industry to remove contaminants and ensure purity.

Understanding Filter Ratings and Standards

When evaluating air filtration systems, it’s important to consider filter ratings such as MERV (Minimum Efficiency Reporting Value). Higher MERV ratings indicate better filtration of smaller particles, which is essential for sensitive environments. For a deeper dive into the benefits of high-efficiency filters, check out this resource on the benefits of a MERV 16 filter for air purifiers.

Common applications for filtration in everyday life

Everyday Uses of Filtration in Homes and Offices

Filtration plays a crucial role in maintaining air and water quality in our daily environments. In homes, air filtration systems are commonly used to remove solid particles like dust, pollen, and pet dander from the air. These systems often rely on filter media such as HEPA filters or activated carbon to capture contaminants and improve indoor air quality. Water filtration is another essential application, with filter cartridges and membrane filtration methods helping to remove impurities from tap water, making it safer for drinking and cooking.

Filtration in Appliances and HVAC Systems

Many household appliances, such as vacuum cleaners and air purifiers, use specialized filters to trap dust and allergens. HVAC systems in both residential and commercial buildings incorporate air filtration to prevent the circulation of pollutants and maintain a healthy environment. The choice of filter medium, whether for air or water, depends on the specific contaminants targeted and the desired level of filtration efficiency.

Everyday Industrial and Commercial Filtration

Filtration is not limited to homes. In offices, restaurants, and other commercial spaces, filtration systems are used to ensure clean air and water for employees and customers. Industrial filtration applications include the treatment of liquids and gases, such as oil and water treatment in manufacturing processes. These systems often use advanced filter media and membrane filtration to handle larger volumes and more complex contaminants.

- Gravity filtration is often used for simple separation of solids and liquids in kitchens and laboratories.

- Flow filtration and vacuum filtration are common in both household and industrial settings for faster processing of fluids.

- Membrane filtration is widely used in water treatment and the pharmaceutical industry to ensure high purity levels.

Understanding the differences between filtration methods and filter types is key to selecting the right system for your needs. For a deeper dive into how HEPA 13 and HEPA 14 filters compare in everyday and industrial applications, check out this guide on HEPA 13 vs HEPA 14 filters.

Specialized filtration needs in healthcare settings

Critical Role of Filtration in Healthcare Environments

Air filtration systems are essential in healthcare settings, where maintaining high air quality is crucial for patient safety and infection control. Hospitals, clinics, and pharmaceutical industry facilities rely on advanced filtration methods to remove airborne contaminants, including bacteria, viruses, and fine particles. The filtration process here often involves multiple filter media, such as HEPA filters and activated carbon, to capture both solid particles and volatile organic compounds.Types of Filtration Systems Used

Healthcare applications demand specialized filtration systems tailored to different needs:- HEPA filtration: High-Efficiency Particulate Air (HEPA) filters are widely used to trap particles as small as 0.3 microns, making them effective against most airborne pathogens.

- Membrane filtration: This method is often used in pharmaceutical cleanrooms to separate solids from liquids and gases, ensuring sterile environments for drug production.

- Activated carbon filters: These filters help remove odors and chemical vapors, improving overall air quality in treatment rooms and laboratories.

- UV-C light integration: Some systems combine filtration with ultraviolet light to neutralize microorganisms, adding an extra layer of protection.

Applications Beyond Air: Water and Fluid Filtration

In addition to air, filtration systems in healthcare also treat water and other fluids. Water treatment is vital for surgical procedures, laboratory analysis, and pharmaceutical manufacturing. Gravity filtration, vacuum filtration, and flow filtration methods are used to ensure that water and liquid gases meet strict purity standards. Filter cartridges and membrane filtration are common choices for these applications, providing reliable removal of contaminants.Ensuring Compliance and Safety

Healthcare facilities must adhere to rigorous standards set by regulatory bodies. The choice of filter medium and filtration methods is often dictated by the need to minimize infection risks and maintain a sterile environment. Regular maintenance and monitoring of filtration systems are necessary to ensure ongoing effectiveness. For those interested in how air purifiers can address specific needs like dust control and pet dander in sensitive environments, you can find more details in this guide on finding the ideal air purifier for pet owners and dust control.Industrial and commercial uses of air filtration

Key Roles of Air Filtration in Industry

Industrial and commercial environments rely heavily on advanced air filtration systems to maintain air quality, protect equipment, and ensure the safety of workers. The filtration process in these settings is more complex than in homes, often involving the removal of solid particles, liquids, and gases from the air and other fluids. These applications demand robust filter media and specialized filter cartridges to handle high volumes and specific contaminants.

Common Industrial Filtration Applications

- Manufacturing: Factories use filtration systems to capture dust, metal shavings, and chemical fumes. This not only protects workers but also prevents contamination of products and machinery.

- Pharmaceutical Industry: Cleanrooms in pharmaceutical manufacturing require strict air filtration to avoid contamination of drugs. High-efficiency filters, including HEPA and membrane filtration, are standard to ensure product purity and regulatory compliance.

- Oil and Gas: Filtration methods are used to separate solids and liquids from oil, gas, and water streams. This improves process efficiency and protects sensitive equipment from damage.

- Food and Beverage: Industrial filtration is essential for removing particles and microorganisms from water and other fluids used in processing, ensuring product safety and quality.

- Water Treatment: Facilities use gravity filtration, membrane filtration, and activated carbon filters to purify water for industrial processes or public consumption.

Types of Filtration Systems and Media

Industrial filtration systems are designed to handle large-scale applications and a variety of contaminants. The choice of filter medium depends on the nature of the particles or fluids being filtered. For example, membrane filtration is effective for separating very fine particles and microorganisms, while activated carbon is used to remove odors and gases. Vacuum filtration and flow filtration are common in chemical processing and pharmaceutical industries, where precise separation of solids, liquids, and gases is required.

| Industry | Filtration Method | Typical Filter Media | Main Purpose |

|---|---|---|---|

| Pharmaceutical | Membrane, HEPA, vacuum filtration | Membrane, HEPA, activated carbon | Product purity, contamination control |

| Oil & Gas | Gravity, liquid-gas separation | Filter cartridges, activated carbon | Protect equipment, improve process |

| Water Treatment | Gravity, membrane, activated carbon | Membrane, activated carbon, sand | Remove solids, purify water |

| Manufacturing | Air filtration, flow filtration | HEPA, filter media, cartridges | Worker safety, product quality |

Challenges and Considerations

Industrial filtration systems must be tailored to the specific needs of each application. Factors such as the type and concentration of contaminants, flow rates, and regulatory requirements all influence the selection of filtration systems and filter media. Regular maintenance and monitoring are crucial to ensure ongoing performance and compliance with industry standards.

Choosing the right air purifier for your application

Key Considerations for Selecting an Air Purifier

When it comes to choosing the right air purifier, understanding your specific filtration needs is crucial. Different applications, whether at home, in healthcare, or in industrial settings, require different filtration systems and filter media. Here are some important factors to keep in mind:

- Type of Contaminants: Identify whether you need to remove solid particles, liquids, gases, or a combination. For example, HEPA filters are effective for capturing fine particles, while activated carbon filters excel at removing odors and volatile organic compounds (VOCs).

- Filtration Methods: Consider the filtration process best suited for your environment. Options include gravity filtration, membrane filtration, vacuum filtration, and flow filtration. Each method has its strengths depending on the application, such as water treatment, pharmaceutical industry, or oil and gas industries.

- Filter Medium and Media: The choice of filter medium—such as fiberglass, pleated paper, or synthetic fibers—impacts the efficiency and lifespan of the system. In industrial filtration, robust filter cartridges or membrane filters are often required for high-volume or specialized applications.

- System Size and Capacity: Match the air purifier’s capacity to the size of your space and the volume of air or fluid to be treated. Industrial and commercial applications may need larger, more powerful filtration systems compared to residential use.

- Maintenance and Replacement: Check how often filters need to be replaced and whether the system allows for easy maintenance. Some filtration systems in the pharmaceutical industry or water treatment require frequent monitoring to maintain quality and process integrity.

- Compliance and Standards: For certain industries, such as pharmaceutical or food processing, filtration systems must meet strict regulatory standards to ensure product safety and quality.

Matching Filtration Systems to Your Application

Different industries and environments demand tailored solutions. For example:

- Home and Office: Air filtration systems with HEPA and activated carbon filters are ideal for improving indoor air quality by removing dust, pollen, and odors.

- Healthcare: Medical facilities often require advanced membrane filtration and high-efficiency filter media to protect patients and staff from airborne pathogens.

- Industrial: Industrial filtration systems are designed to handle large volumes of air, water, or process fluids, often using specialized filter cartridges and robust filter media to capture solids, liquids, and gases.

- Water and Oil Treatment: Gravity filtration and membrane filtration are common in water treatment and oil processing, ensuring removal of contaminants and maintaining fluid quality.

Ultimately, the right air purifier or filtration system depends on your specific application, the contaminants present, and the required level of filtration. Assessing these factors will help you select a system that delivers reliable performance and maintains the desired air or fluid quality in your environment.

Future trends in air filtration technology

Emerging Technologies in Filtration Systems

Air filtration is advancing rapidly, driven by the demand for cleaner environments in homes, industries, and healthcare. New filtration methods and filter media are being developed to capture even smaller particles, improve energy efficiency, and extend filter life. For example, membrane filtration and advanced activated carbon filters are now common in both water treatment and air filtration applications. These innovations help remove a wider range of contaminants, from solid particles to liquids and gases, making filtration systems more versatile across different industries.

Smart Filtration and Automation

Modern filtration systems are increasingly integrating smart sensors and automation. These features allow real-time monitoring of air quality and filter status, ensuring that the filtration process remains effective. In industrial filtration, automated systems can adjust flow rates or switch filter cartridges based on detected contaminants, optimizing the process and reducing maintenance. This is particularly valuable in pharmaceutical industry settings, where maintaining high air and fluid quality is essential for product safety.

Focus on Sustainability and Efficiency

There is a growing emphasis on sustainable filtration solutions. Manufacturers are developing filter media that are recyclable or biodegradable, reducing the environmental impact of used filters. Energy-efficient filtration systems are also gaining traction, especially in large-scale industrial filtration and water treatment plants. These systems use less power while maintaining high performance, which is crucial for industries looking to lower operational costs and meet environmental regulations.

Expanding Applications Across Industries

Filtration technology is being adapted for new applications beyond traditional air and water treatment. For example, vacuum filtration and gravity filtration are now used in oil and gas industries to separate solids from liquids and liquids from gases. Pharmaceutical industries rely on advanced membrane filtration to ensure the purity of fluids and gases used in production. As filtration methods evolve, more industries are adopting specialized systems to improve process quality and safety.

What to Watch For

- Growth in flow filtration and membrane filtration for both industrial and residential use

- Development of filter cartridges with longer lifespans and higher efficiency

- Integration of digital monitoring and predictive maintenance in filtration systems

- Increased use of activated carbon and other advanced filter media for targeted contaminant removal

As filtration technology continues to evolve, the focus remains on improving air and fluid quality, enhancing process efficiency, and meeting the specialized needs of various industries. Staying informed about these trends can help you choose the right filtration system for your application, whether it’s for home, healthcare, or industrial use.