The Basics of Air Compressor Oil-Water Separation

Introduction to Oil-Water Separation in Air Compressors

The intricate workings of an air compressor system involve compressing air to utilize it efficiently for various applications. But in doing so, a common byproduct emerges: condensate. This mixture, comprised chiefly of oil and water, necessitates the use of an effective oil-water separator. The goal of this component is to ensure that the condensate does not damage the components of the compressor or interfere with the quality of the compressed air.The Significance of Proper Oil-Water Separation

In an air compressor system, the removal of oil and water through effective separators is crucial to prevent damage and maintain the reliability of shipping and other industrial environments. This process is particularly important considering the high capacity cfm (cubic feet per minute) that many air systems operate under. The damage that unchecked moisture can do to air supply and air systems is profound, emphasizing the vitality of ensuring sufficient service life for compressors. Operators must choose the right model of oil-water separator, taking into account critical factors such as temperature oil tolerances and how appropriately it's sized (compressor-specific). It’s important to note that the connection npt (National Pipe Thread) must align with the system specifications to sustain optimal functionality. For individuals and industries looking to buy these separators, understanding the product and its specifications – such as the designed remove capacity and filtration capabilities – is essential. Additionally, policies on free shipping or stock availability can influence purchasing decisions for those involved in the operation and maintenance of these systems. For more information on enhancing air quality within compression systems and air purification, consider reading about enhancing indoor air quality with air conditioning and purification.Why Oil-Water Separation Matters

Significance of Oil-Water Separation in Air Systems

The importance of the separation process in air compressors cannot be understated. When air is compressed, it often brings along oil and water, creating a blend that leads to several complications. Thankfully, technology has brought forth solutions, like the air compressor separators, designed to remove these unwanted elements efficiently. In any compressed air system, maintaining the oil-water balance is crucial. Oil can facilitate the smooth operation of compressors, but its mixture with water can result in sticky emulsions. These emulsions can obstruct air supply lines and degrade the quality of air sent through the system. By using efficient filtration methods, such as activated carbon filters and separator service kits, the longevity or service life of your air compressors is significantly improved. Moreover, proper separation ensures compliance with environmental policies. By using the right separator model, businesses can avoid the release of polluted condensate, safeguarding ecosystems and achieving regulatory standards. In shipping and industrial settings, where large quantities of air are compressed, the separator's role becomes even more critical. With capacities measured in cfm, having a correctly sized compressor is vital to handle the workload effectively and maintain consistent performance. Also, it's essential to consider the connection NPT, temperature oil tolerance, and the specific design features, as they can heavily influence the efficiency of oil-water separators in the air filtration process. Businesses often opt for oil water separators with attributes that cater to their specific operational needs. To fully comprehend the role played by these separators and to optimize the performance of your air systems, understanding the dynamic nature of airflow is beneficial. For more insights into this subject, you can explore further here. Utilizing effective filtration not only adds value to air systems but also ensures a reduction in maintenance costs. By consistently investing in high-quality air separator products with complimentary benefits, like free shipping and stock availability, businesses can uphold superior operational standards.Types of Oil-Water Separators

Diverse Approaches to Oil-Water Separation in Air Systems

The importance of effectively separating oil and water in compressed air systems is underscored by the wide variety of separators available, each designed to meet specific needs and operational conditions. Different products incorporate diverse methods, and understanding these can help you choose the right model for your system.

Many air compressors employ centrifugal separators. These utilize spinning chambers to effectively separate oil and water from the air by taking advantage of centrifugal force. They are particularly effective in environments with high temperatures and boast robust service life when paired with proper maintenance and the right service kits.

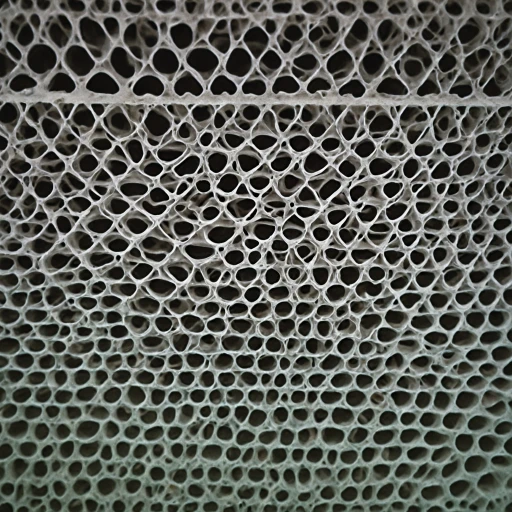

For systems requiring high levels of filtration, coalescing filters remain a popular choice. Designed to remove aerosols, coalescing filters offer high efficiency by trapping oil and water particles, allowing ship-fit air to be cleaner and thereby enhancing the overall capacity in cfm.

- Activated Carbon Filters: Deployed after initial separation, these filters refine the air by absorbing remaining oil vapors.

- Condensate Management Systems: Handle the disposal of separated condensate, ensuring compliant, eco-friendly operation.

Understanding the connection NPT (National Pipe Thread Tapered), temperature oil compatibility, and proper sizing is crucial when selecting a separator. It's necessary to factor in these aspects to avoid complications and optimize the overall performance of your air compressor.

Installation and Maintenance Tips

Installation Considerations for Optimal Performance

Proper installation of an oil-water separator is crucial to not only ensure its efficiency but also enhance the overall lifespan of your air compressor. When integrating the separator into your air system, consider the size of the compressor to match the capacity in cubic feet per minute (cfm). This ensures the separator can handle the volume and pressure of compressed air effectively.Placement and Connection for Effective Operation

When placing the separator, prioritize areas with easy access for maintenance and inspection. Ensure the connection is compatible with the network's national pipe thread (NPT) standards for optimal fitting. The location should mitigate temperature fluctuation risks, particularly for the separator oil, to maintain efficiency.Maintenance and Service for Longevity

Regular upkeep is indispensable to maintaining the separator's performance. Utilize service kits tailored to your separator model, as they are designed to address typical wear and tear issues systematically. Pay attention to the separator's filter to prevent contamination from oil and water. Regularly inspect the condensate discharge line to prevent clogging, which could impede the separator's functionality.Ensuring Compliance and Policy Adherence

Adhering to environmental policies regarding the disposal of separated oil and water is crucial. Choose products that offer clear guidelines and support free shipping services for the replacement parts to ensure timely maintenance. By closely aligning with guidelines, you not only prolong the service life of your equipment but also comply with environmental standards.Challenges with Shipping and Stock Availability

Understanding potential challenges such as delayed shipping or stock shortages can better prepare you for maintaining an uninterrupted air supply. By preemptively stocking essential components like service kits, you can mitigate downtime effectively, continually driving the efficient operation of your compressed air system.Common Challenges and Solutions

Tackling Common Challenges in Oil-Water Separation

Operating an oil-water separator in an air compressor system comes with its own set of challenges. These issues can affect the efficiency, longevity, and overall performance of the compressed air system if not addressed properly. Let's explore some of the typical challenges and solutions.

- Consistent Monitoring: It's essential to regularly check the performance of the oil-water separator to ensure it's efficiently removing oil from the water. This is crucial for maintaining clean air supply and avoiding contaminants that could damage the system.

- Handling Variability in Condensate: Oil-water separators must be able to handle varying amounts of condensate. Systems designed to accommodate different capacity CFM and temperature oil levels can manage fluctuating amounts, preventing overflow or underperformance.

- Proper Sizing: An inadequately sized compressor combined with its separator may lead to inefficient filtration. Ensuring the separator’s capacity fits the air system involves understanding the specific needs of your model, including flow rates and connection npt.

- Maintenance and Servicing: Regularly replacing filters and using service kits helps in extending the service life of the oil-water separator. Keeping a steady stock of these products can expedite maintenance processes without downtime.

- Addressing Shipping Constraints: Whether dealing with free shipping options or backorders, timely access to replacement parts like oil water separators can impact performance. It's advisable to have a view of your shipping policy to prevent delays.

By addressing these common obstacles proactively, you can optimize the productivity and longevity of your compressed air system. Understanding and implementing the right solutions ensures a cleaner and more efficient air supply, which is essential for the optimal operation of your machinery.