What is an Air Compressor Intake Filter?

Introduction to Air Compressor Intake Filtration

In the realm of air compressors, the air compressor intake filter stands as an indispensable component, pivotal to the efficient operation of the entire system. Primarily, its role revolves around safeguarding the air compressor by filtering out contaminants from the air intake, providing a protective barrier that enhances longevity and performance.

An air compressor intake filter functions much like a sentinel, meticulously screening incoming air to remove particulates and debris that may otherwise compromise the compressor's internal components. Often comprised of paper or synthetic filter elements housed within a durable metal casing, these filters ensure only clean air enters the system. This not only prevents potential damage but also optimizes the machine's efficacy.

Designs may vary, encompassing everything from standard rand and ingersoll types to specialized configurations featuring add-ons like a silencer metal, muffler, or compressor silencer, all designed to reduce noise and improve operational smoothness. It's also common to see variations in filter elements and housing materials, tailored to different compressor applications and environmental conditions.

How Air Compressor Intake Filters Work

How These Air Gems Work

Understanding how air compressor intake filters operate begins with recognizing their core function. These filters are tasked with purifying the air drawn into the compressor. As air travels through the intake, the filter captures contaminants like dust and debris, safeguarding the compressor's internal components. The mechanics behind these filters are straightforward yet effective. Filter elements crafted from paper or metal are housed within the filter silencer, playing a critical role in this process. The design, often incorporating a silencer housing or metal intake, muffles noise and manages air flow efficiently. Brands like Solberg or Ingersoll Rand engineer these systems to ensure optimal performance and durability. Moreover, certain filters are fitted with a replacement air silencer to further enhance noise reduction capabilities. This noise reduction, combined with effective filtration, contributes to a quieter and more efficient work environment when using air compressors. For maintenance and longevity, understanding the difference between paper elements versus filter metal or composite materials is crucial. Choosing the right type of air filter can impact performance and cost efficiency. Some filter elements are more affordable to replace, translating to not just immediate savings, but extended compressor usability. In heavy-duty settings, such as on ships or industrial environments, the ability to efficiently replace these filter parts ensures the compressors run at optimal capacity while maintaining a clean and safe air supply. It's wise for businesses to keep backup stocks in store, particularly critical items like npt filter elements, to mitigate potential downtime. For more detailed information on selecting the appropriate filters for your specific needs, including compressors and humidifiers, check out this guide on choosing the right filters for your humidifier. This resource can provide deeper insights into making informed choices when it comes to crucial air filtering components.Benefits of Using an Air Compressor Intake Filter

Advantages of Incorporating Air Compressor Intake Filters

Incorporating an air compressor intake filter is essential for maintaining optimal functionality and longevity of your compressor system. These filters provide a host of advantages that ensure efficient operation and protection of the internal components.- Enhanced Air Quality: By eliminating dust, dirt, and other contaminants, intake filters help improve the quality of the air that flows into the compressor. This clean air reduces the risk of wear and tear on the compressor's moving parts.

- Prolonged Equipment Lifespan: Cleaner air leads to less abrasion and corrosion, contributing to a longer lifespan for equipment. A reliable intake filter acts as a guardian, preserving crucial elements like the compressor air intake and compressor filter components.

- Energy Efficiency: Filters like the silencer metal or filter elements can enhance the energy efficiency of your system by decreasing the workload on your compressor. This is accomplished by preventing clogs that require the compressor to use more energy.

- Noise Reduction: Some intake filters come with a muffler or a filter silencer, which reduces the operational noise. This can be a significant benefit in industrial settings or where noise pollution is a concern.

- Cost-Effective Maintenance: Regularly changing the filter element, whether it’s a paper, metal, or replacement air type, can prevent costly repairs. When filters are carefully chosen and installed, they save costs associated with rundown equipment and unexpected downtime.

Types of Air Compressor Intake Filters

Exploring the Different Varieties of Intake Filters

When it comes to air compressor intake filters, the options are varied, each offering distinct features that cater to specific needs. Whether you're dealing with small personal compressors or industrial giants, understanding these differences is crucial for optimal performance.

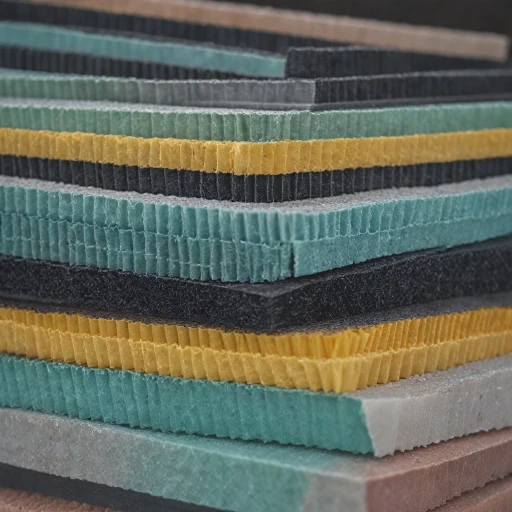

One common type of intake filter is the paper filter element. These are often cost-effective and easy to replace, making them a popular choice for those seeking a balance between efficiency and price. However, paper filters might require more frequent changes due to their susceptibility to clogging.

Metal intake filters are another option, providing a durable alternative to paper. Made from materials like aluminum or steel, these filters are more resilient and can withstand harsher conditions, which is beneficial for industrial applications or environments with high levels of contaminants.

For applications requiring noise reduction, the combination of a filter silencer might be considered. These systems not only filter the incoming air but also reduce the noise created by the air intake process. It's essential for creating a quieter working environment, especially in confined spaces.

Brands like Ingersoll Rand and Solberg offer specialized filters suited for various compressor models. For those using specific compressors like Ingersoll Rand, sourcing filters directly from them ensures compatibility and efficiency.

Moreover, some advanced intake filter systems incorporate a filter replacement indicator which provides a visual cue when it’s time to replace the filter element. This minimizes the guesswork and helps maintain the optimal performance of the air compressor.

For those interested in exploring further, understanding the role of additional filtration technology can deepen your comprehension of air quality management in comprehensive systems.

Maintenance Tips for Air Compressor Intake Filters

Essential Maintenance Strategies

Regular maintenance of your air compressor intake filter is key to ensuring optimal performance and longevity. Proper care helps in maintaining the efficiency of the air intake system and prevents potential issues that might compromise the compressor's functionality. Here are some maintenance strategies you can follow:

- Regular Inspection: Consistently inspect the filter element for signs of wear and tear. Look for damage or accumulation of dirt that might affect performance. Both paper and metal elements require periodic checks.

- Replacement Schedule: Follow the manufacturer's guidelines on the replacement frequency of the air filter. Some filters, such as those from ingersoll rand and solberg, have specific timelines for when they should be replaced.

- Cleaning the Filter: Depending on the filter type, you may need to clean the filter housing and element to remove dust and debris. This is especially important for maintaining efficiency in silencer metal and compressor silencer models.

- Stocking Replacements: Always have filter replacements readily available in your store. This ensures that you can promptly address any changes in intake filter performance without significant downtime.

- Filter Silencer Check: If your system includes a filter silencer, routinely check its condition and npt connections. Ensure that the silencer housing remains secure and free from obstructions.

- Monitoring Filter Prices: Keep an eye on the price trends for various filter elements, whether they're element air or intake paper types, to ensure cost-effective replacements.

By adhering to these maintenance tips, you can enhance the reliability and performance of your compressor air system, ensuring a longer service life and reducing the risk of unexpected issues.